Pressure metrology

Examples for our production processes and methods

JAKO operates its own special machine construction division to make sure that JAKO measuring instruments meet the highest quality and performance requirements and can be cost-effectively produced. The example of dial pressure gauges gives you some insight into our different production methods and facilities.

Connection pins

Turning and milling processing of many materials

|

|

|

Movement of the pointer - highly precision

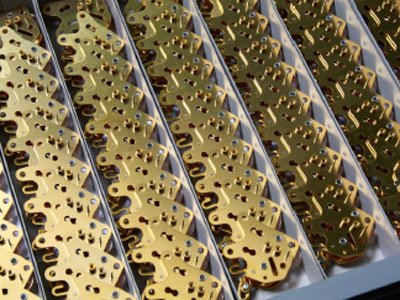

Punching parts made of brass, nickel silver or stainless steel

|

|

|

Bourdon tube - measuring element

Manual assembly

|

|

|

Chemical seals

Manual and semi-automatic welding and soldering processes

|

|

|

Fluid damped measurement systems

Water-tight welding, vacuumising, filling with damping fluid

|

|

|

Pressure gauge adjustment

High-precision intermediate and final tests

|

|

|